The museum of the industrial salon displays exhibits from the former factory for television electronics (WF). The WF was one of the “high-tech centers” of the GDR – and with about 9,000 employees, the largest factory in East Berlin. It operated – under changing names – from 1945 to 1992 on the premises between Ostendstrasse and Wilhelminenhofstrasse on the Spree River.

The products manufactured included television picture tubes, transmitter tubes and special tubes, and increasingly also semiconductors such as light-emitting diodes. After reunification, the plant was converted into a limited liability company and initially had 1,400 employees. In 1993, the color picture tube plant was taken over by Samsung Korea and continued to produce color picture tubes with about 800 employees. With the transition to flat screens, picture tube production was replaced by new technologies. The picture tube plant in Schöneweide was closed at the end of 2005.

WF Collection

The permanent exhibition shows, among other things, workplaces with tools and machines for the production of special tubes. Also exciting are individual products, pioneers for later mass production and milestones of technological development. These include the

large electronic Toccata organ, the small Vocata melody instrument, the microwave oven of the GDR, jammers against radio stations in the West…

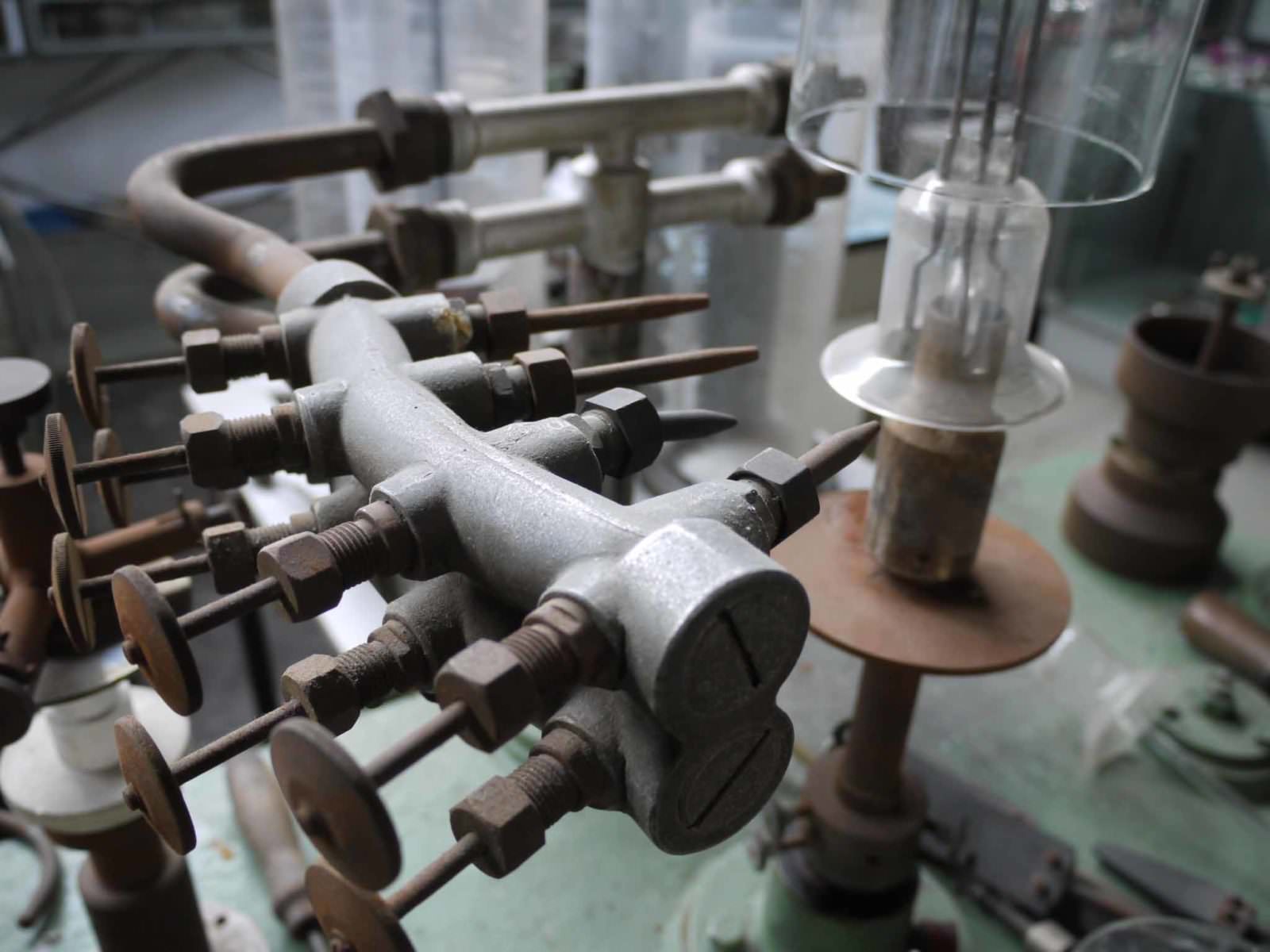

Manufacturing equipment, tools, machine

Special measuring tables for tube types like SRS 551

Vertical melting machine for glass flasks in tubes

Glassblower workstation for the blowing of individual parts

Metal-ceramic joints for the tube structure

Show of electron tube families and examples of their application

In 18 illuminated wall display cases, the entire range of internationally common electron tube families is exhibited, which originate from the long-standing production of the WF.

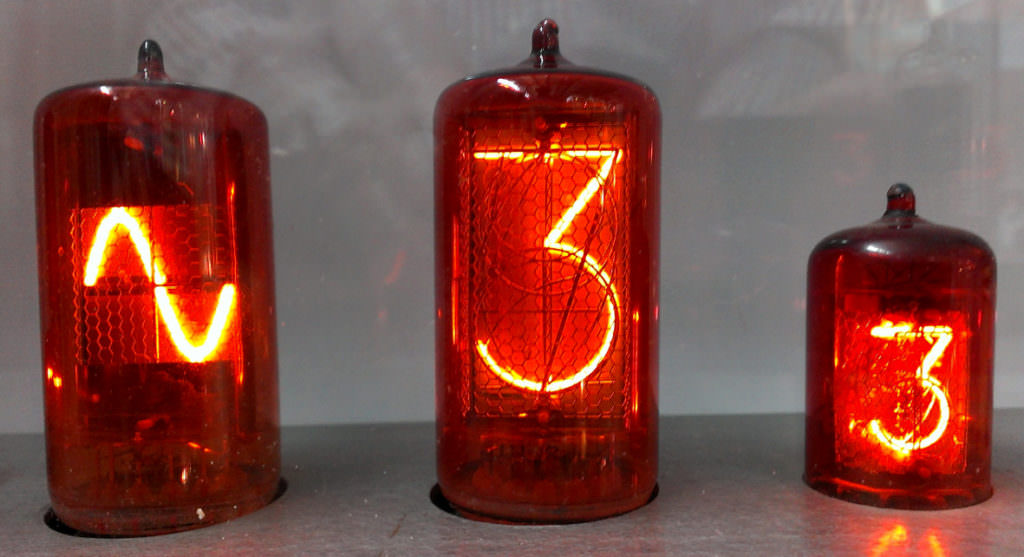

Digit display tubes – produced in the WF since the beginning of the 60s. They were used e.g. in clocks, desk calculators, measuring instruments.

The wide product range

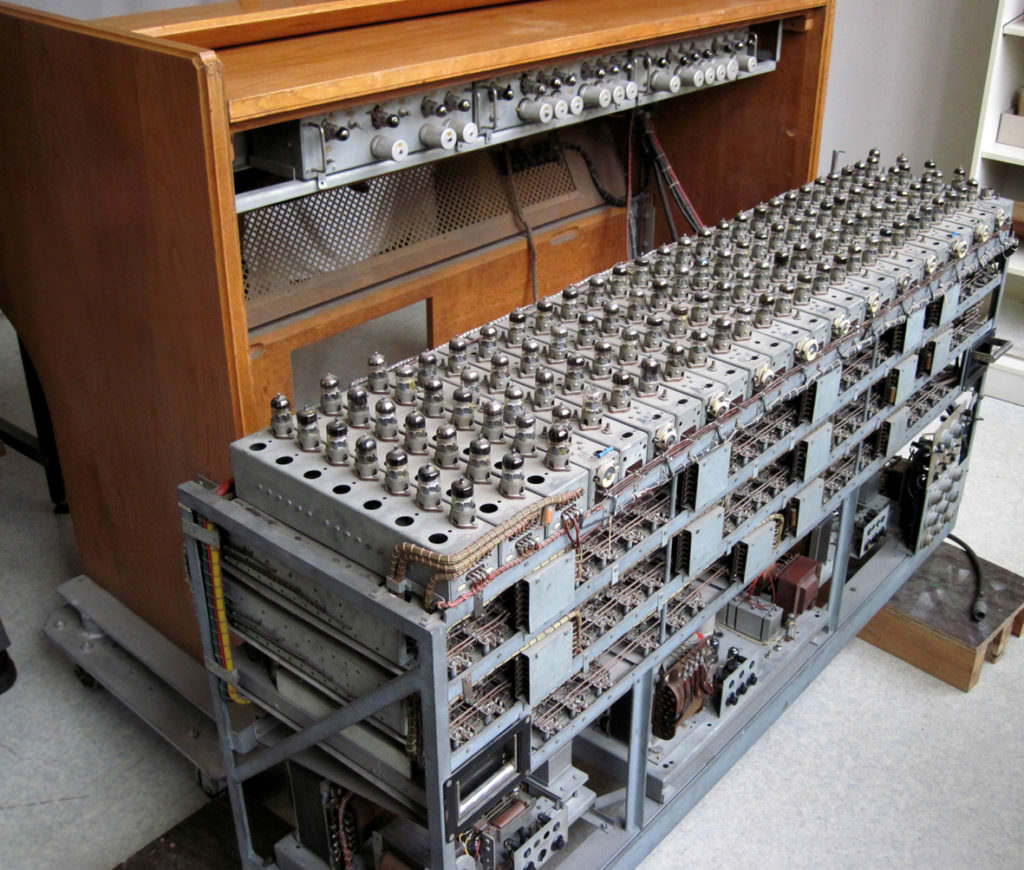

This Toccata organ, unique in the world, was developed and built in 1954 as a prototype at the Telecommunications Plant (later WF). It consists of more than 250 electron tubes and various components and it perfectly imitates the sound of a pipe organ.

From 1961 to 1989, it was in use at the Komische Oper in Berlin.

It has great significance for the development history of electronic musical instruments. The developer Ernst Schreiber was able to incorporate the results of his research into the sound characteristics of a Silbermann organ into the development. Special tone generator circuits and frequency dividers were used for sound generation. The sound is shaped by elaborate filter systems.

Connected with the development of electronic organs was the hope of a foreign exchange-generating business. They were also intended for movie theaters, cinemas, and houses of culture. Of a total of four organs built in the WF, only this one has survived. For the high cost of materials (very expensive)and

political reasons (organs are often church musical instruments) led to the abandonment of further development.

Christmas 1952 saw the opening of the GDR’s public television program with the “Current Camera”. The VEB Werk für Fernmeldewesen (the later WF) played a leading role in the development of the first industrially manufactured camera series.

Initially, the scanning tubes for the studio cameras of television and transmitting equipment for telecommunications were produced here. However, as the lack of competence and production-technical deficiencies became apparent very quickly, the hopes for production-ready product lines with the highest level of perfection at world level were not fulfilled,

Selected exhibits from the collection to the work for television electronics (WF).

One of the permanent problems of everyday life in the GDR was the procurement of goods for daily use and “consumer goods. Many products that were already in use in private households in Western industrialized countries at the time could not be purchased at all in GDR retail stores, or only much later. As purchasing power increased, so did the people’s resentment of the inadequate supply.

The social mandate formulated by the party and the government was intended to provide a remedy.

It instructed companies to produce five percent of their goods as consumer goods. The WF also had to produce consumer goods in addition to its actual production tasks.

One example is the SL 3 flash unit, which was produced by VEB Elgawa Planen. The price in the production year 1974 was 75Mark of the GDR.

This mains flash unit requires rechargeable batteries. After each flash photo it must be recharged from the mains socket.

In order to be able to take photos in a more mobile way, the BZG 1 accessory unit was developed and manufactured in the factory for television electronics. This significantly increased the radius of action of photographers with flash units. Four mono cells served as power sources. The “mains flasher” generated a 220 V alternating voltage. The BZG was also popular as an “aid” used by anglers for fishing.

For this purpose, two wires were immersed in water as electrodes. The 220 volt alternating voltage ensured beautiful catch results!

No other Eastern bloc country had such a high standard of living as the GDR. Nevertheless, many goods were difficult or impossible to obtain.

Sometimes there was a shortage of flow heaters, then again of typewriters or leather shoes. Many GDR citizens had a bag in their pocket in case there were bananas or oranges somewhere. A whole barter system developed to get coveted things away from official channels. The glassblowers in the factory for television electronics also benefited from this. As artistic craftsmen, they were highly respected. Typically, the many glassblowers worked in tubular and vacuum techniques. Only colorless glasses were used for the glass bulbs.

In order to obtain the colored raw glass for particularly desirable ornamental objects, they used private contacts, mostly to Thuringia. From colored glass they then made figurines, Christmas tree tops, tobacco pipes, mugs – popular exchange objects “for home” – in the GDR typical abbreviation “fzh”. At the top of the popularity were drinking vessels – like the cognac snifter exhibited here. Such glasses were at times considered a “second currency”, not only in the WF. This “sideline” was not legal for the glassblowers either. But everyone knew about it and took advantage of the opportunities. The work was often rewarded with spirits. A bottle of “Brauner” or

“Weißer”, were common means of payment.

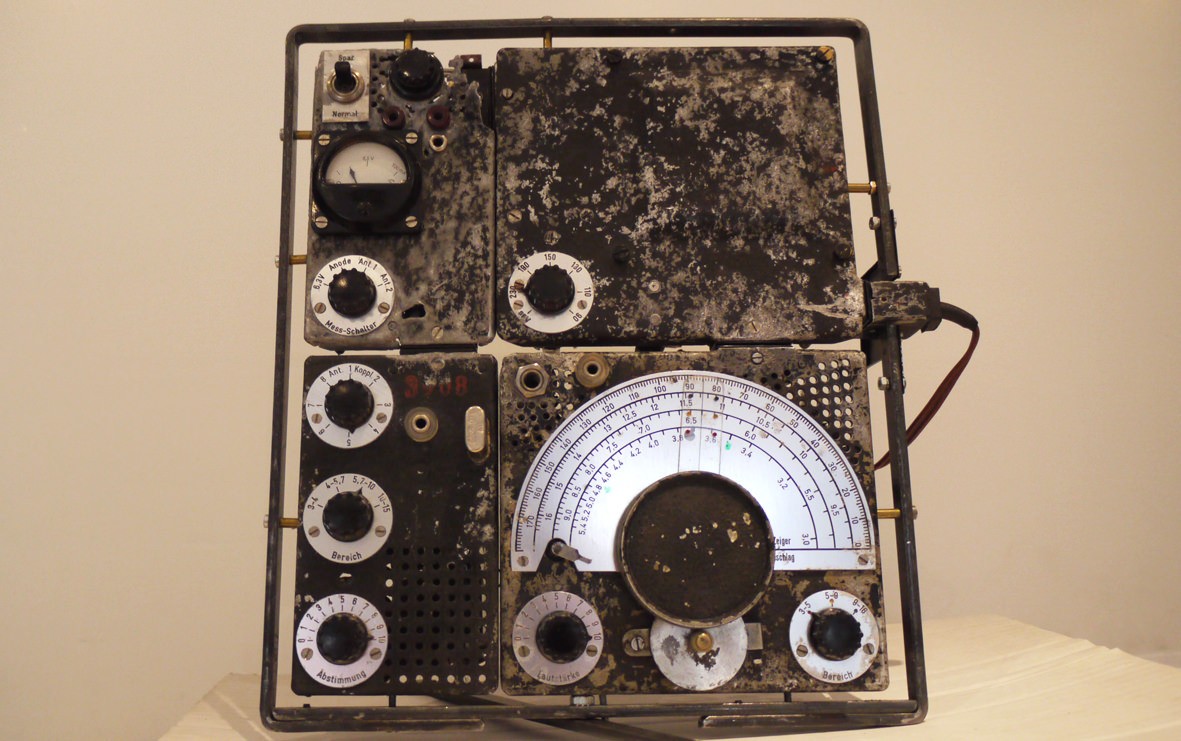

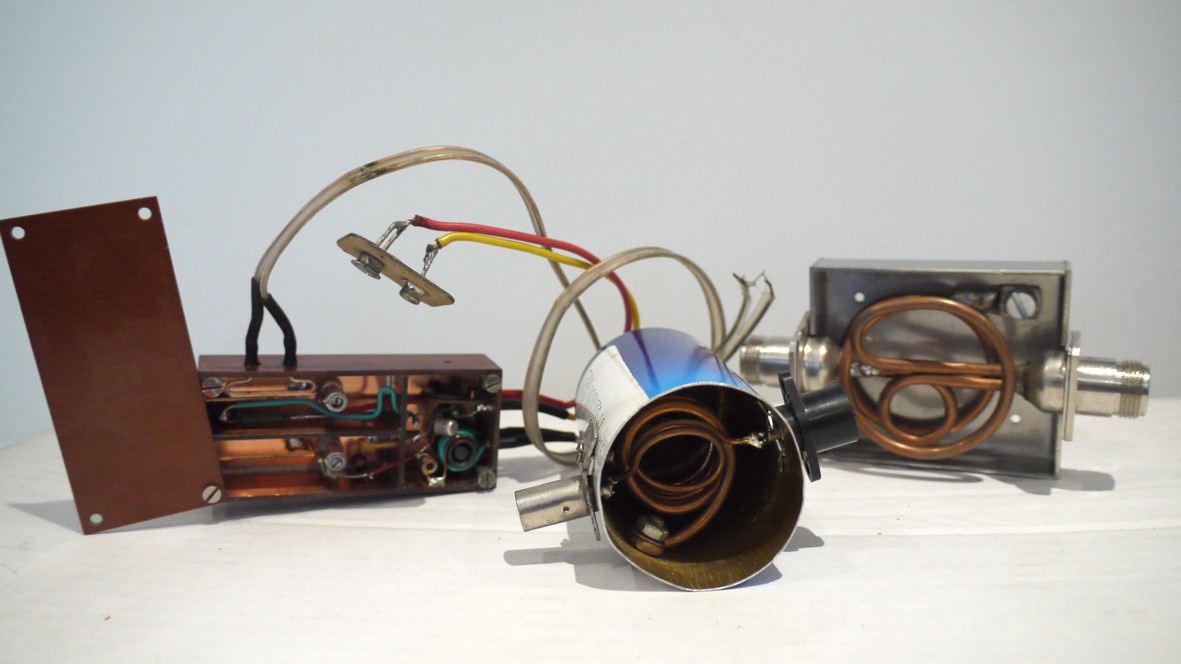

In the early 1990s, several packages were found wrapped in foil during earthworks in Helmholtzstrasse. The finder identified them as electronic devices and took them to his arbor. Then, in the fall of 2017, he decided to give the find to the industrial salon. Here, the modules were put together. It is the agent radio of the type “12 WG”, which was developed and built in 1951/52 by the Gehlen organization – precursor of the West German Federal Intelligence Service. Apparently, an agent had hidden it in the earth depot in the mid-1950s, before the Wall was built. It remained there for almost 30 years.

Among the finds is also a small tin container with headphones, Morse key, 22 oscillating crystals of different frequencies, spare tubes (from USA production), antenna wire, insulators for the antenna suspension, banana plugs and spare fuses, as well as ciphering and deciphering documents. The 30 years in the ground have left strong traces. Especially the aluminum front plates and the aluminum plate segments of the variable capacitors have suffered. Almost all electron tubes have “pulled air” and are unusable. But a radio amateur from the industrial salon nevertheless succeeded in establishing a tactile radio connection to Müggelheim.

Conjecture: The device seems never to have been used. Maybe it was buried by a “Schlaeferfunker”, who should be woken up only in case of war or tension. He maintains contact with the service he works for, but in order not to be exposed, he lives normally and does not keep a recognizable connection.

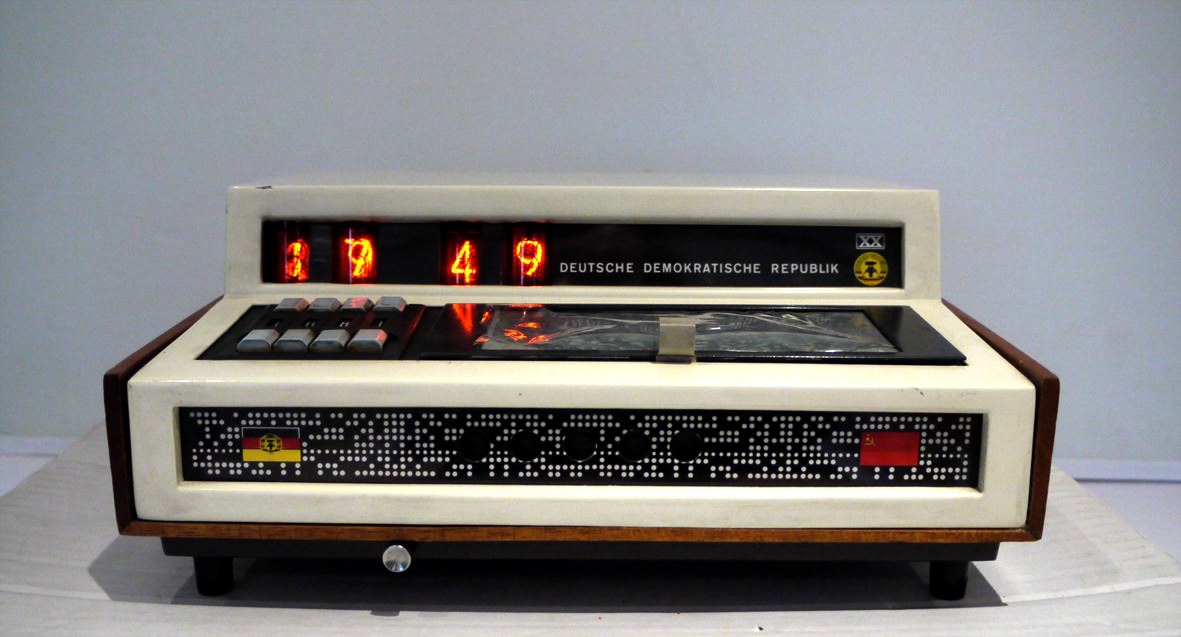

On October 7, 1969, the GDR celebrated its 20th birthday. To mark the occasion, the factory for television electronics received a special order from the Ministry of Electrical Engineering and Electronics: the development and construction of a small number of luxurious watches – with their own case.

They were intended as “representative gifts” for heads of state and party leaders of friendly states and “deserving comrades”. By circumventing the legally prescribed ordering procedures, large quantities of material had to be procured for them off-plan. Recognizing these facts, the Ministry of Electrical Engineering/Electronics then also provided special powers and official cars.

The clock played a few bars of the national anthem of the GDR when the alarm function was triggered. Thanks to the primitiveness of the circuit and the tiny size of the built-in loudspeaker, however, the whole thing sounded pathetic. The time clock was provided by a mechanical movement from Ruhla, the display was built with the electronic components of the WF available at that time with digit display tubes. The case is decorated with symbols, which like the ‘XX’ indicates 20 years of existence of the GDR. The GDR and the USSR flags are supposed to symbolize the “unbreakable friendship” with the Soviet Union. The lower front area is adorned by a symbolized perforated strip. It is probably supposed to embody scientific and technical progress, “the basis for the further successful development of the GDR”.

Already a few days after the anniversary, word got around that the reliability of the clocks was indeed very low. Opinion of an engineer from the WF about this clock: “You really couldn’t denigrate the GDR and its electronic industry any worse.”

Disturbed television pictures – mostly they make angry and sometimes they lead to tinkering. In the 60’s there was no second TV program in the GDR. The TV receivers were not set up for it. As early as 1961, ZDF went on the air in the FRG, arousing great interest among the GDR population. To receive the second programs, however, UHF converters were needed, which unfortunately remained in short supply. Thus began a lively tinkering activity – a veritable “do-it-yourself wave”. At first, the construction plans were passed on under the hand, later also GDR technical periodicals published detailed building instructions. If a strong transmitter signal was available, a simple circuit was sufficient: Metal cans were suitable as tuner housings. Inserted in them were metal partitions with a tube oscillator that had to be able to oscillate in the range up to over 500 MHz and a germanium mixing diode. With the time the construction plans became technically better, a second tube improved the mixing amplification. The suitable transistors were smuggled into the GDR – for example in the luggage of “West travelers”.

There was a special feature in the Saxon area. Radar installations of the Soviet military and also Czech transmitters interfered with ZDF reception. To counteract this, one helped oneself with self-built blocking circuits in the antenna line, which could be tuned to the interferer and strongly attenuated it. They were soldered together from adventurous components and well camouflaged. With a little skill, unwelcome interference could be eliminated.

Das Fernsehgerät „Leningrad T2“ war das erste, in der DDR in Serie gebaute Fernsehgerät. Es stellte eine Kombination aus Fernseher und Radio dar. Ursprünglich war das Gerät in der Sowjetunion entwickelt und konstruiert worden. Ab 1950 wurde er dann in der DDR als „Reparationsgut“* gefertigt. Das Sachsenwerk in Radeberg (Rafena) setzte das Gerät zusammen. Und das Fernsehwerk in Oberschöneweide (das spätere WF) musste dafür die gesamte Röhrenbestückung liefern. Das war für das Werk eine enorm anspruchsvolle Aufgabe. Die technischen Voraussetzungen mussten dafür völlig neu geschaffen werden. Aus dem Nichts heraus wurden die Fertigungseinrichtungen konstruiert. Und die Glaskolben wurden unter schwierigen Bedingungen aus der Lausitz beschafft.

Täglich mussten vorgegeben Stückzahlen gefertigt werden. Wurden diese Vorgaben nicht erreicht, wurden die Werkstore geschlossen, niemand durfte

den Arbeitsplatz verlassen. Insgesamt wurden etwa 130.000 Geräte gebaut. Bis zur Produktions-Einstellung im Jahr 1954 sind nur ca. 3.000 Geräte in der DDR verkauft worden. Sie kosteten stolze 3500,- Mark – bei einem damaligen durchschnittlichen Monatseinkommen von rund 300 Mark. Gerüchte sagen, dass Stalin selber am Design mitgewirkt hat. Da er sich angeblich vom „Fernsehauge“ überwacht fühlte, konnte die Bildröhre durch eine mit Stoff bespannten Schiebetür abgedeckt werden. Nach dem Auslaufen der sowjetischen Aufträge wurde das Fernsehgerät ‘Rembrandt’ entwickelt, das es dann auch in der DDR zu kaufen gab.

* Reparationen waren eine Form der Entschädigung, die Deutschland für die Verbrechen und Schäden im 2. Weltkrieg zahlen musste.

For decades, the development and production of picture recording tubes for television cameras belonged to the VEB Werk für Fernsehelektronik (WF). The relatively small division in the large plant was the sole manufacturer in the GDR for this purpose. The tubes were used in various cameras: For industrial purposes, for object surveillance and also in the studio area in the era of black-and-white television. Color television could no longer be realized with the recording tubes from the WF; imports were necessary for this. From the beginning of the 80’s the development of light-sensitive semiconductor structures began. The exhibited camera is the best example. It has a CCD matrix L220 CA, produced in 1989 – as the climax and conclusion of the development. This camera had a resolution of 300,000 pixels. It was suitable for the 525-line television format of the time.

The necessary electronics for control and initial signal processing were contained in an additional U2200 PC circuit, which was developed in cooperation with the ZMD Dresden company. However, the cost of this development was very high. But the “strong interest” of the state and party of the GDR made the further planning possible: The development of camera chips was to continue in a ‘microoptoelectronics center’ in Berlin-Hohenschönhausen. This never came to pass. In 1990, the building that had already been started was torn down again. Today, development is far advanced. Every cell phone can contain several complete color cameras. But this camera shows that possibilities for further technological development were certainly available in the GDR.

“There is still much more to get out of our factories!” Erich Honecker, 1981

Easy to recognize: The pretty object on display here is a kerosene lamp. But what is it made of? And how was it made? A closer look reveals components that are also used in the construction of electron tubes. In fact, an engineer from the WF built the lamp at home. In this case, it was a “take” after the fall of the Berlin Wall, at a time when production had ceased and most of the machines and materials ended up on the scrap heap. Individual parts could be bought privately for small money at WF-GmbH

In GDR times, however, “thefts from people’s property” were quite common. Although bag checks were to be feared when leaving the factory. However, they did not take place one hundred percent in the WF either. A security guard at the exit made sure that everyone pressed the lever of a small box. If a light came on, he had to go to a separate room to check it.

Needed items were therefore disassembled into small, pocket-sized parts. And professionally reassembled at home. Resourceful employees of the WF even managed to get all the parts together in this way to make their own TV sets – even before TV sets were regularly on sale in the GDR!

You can read more about this in the brochure “How I experienced the beginning of television” by Bernhard Drewitz – available at the counter of the industrial salon.

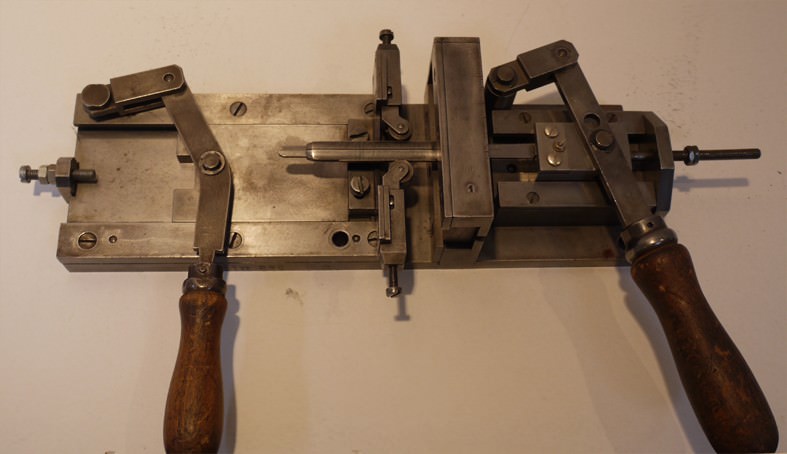

A variety of auxiliary tools were required for the production of electron tubes. These were not available for purchase anywhere. But the toolmakers at the WF were inventive. They also manufactured auxiliary tools in individual production. A simple but clever auxiliary tool is this stretching device. It ensured that the newly wound control grids for electron tubes received their ‘finishing touches’. The grids, as they come out of the winding machine, consist of two metal bars wound with fine wire that has been electrically welded to the metal bars.

This ‘unfinished’ mesh is placed on a metal tongue of the stretching device, and by means of a lever it is possible to smooth the lateral welds on the metal webs by means of two metal pressure rollers. Then a second lever is used to manually spread the metal tongue, which is slotted lengthwise, by a precisely measured amount. This stretches the fine winding wires of the grating and thus increases their mechanical stability. The new grid is thus also brought to the required final dimension and is then ready for installation.

A large number of auxiliary tools were required for the production of electron tubes. These were not available anywhere. But the toolmakers at the WF were inventive. They also manufactured auxiliary tools in individual production. A simple but clever auxiliary tool is this stretching device. It ensured that the newly wound control grids for electron tubes received their ‘finishing touches’. The grids, as they come out of the winding machine, consist of two metal bars wound with fine wire that has been electrically welded to the metal bars.

This ‘unfinished’ mesh is placed on a metal tongue of the stretching device, and by means of a lever it is possible to smooth the lateral welds on the metal webs by means of two metal pressure rollers. Then a second lever is used to manually spread the metal tongue, which is slotted lengthwise, by a precisely measured amount. This stretches the fine winding wires of the grating and thus increases their mechanical stability. The new grille is thus also brought to the required final dimension and is then ready for installation.

Microwave oven with magnetron ans the WF

In the sixties, the WF produced various magnetrons intended for industrial use, primarily for radar systems and in the medical field. So it was obvious to develop a microwave oven as well. With the magnetron HMD 241, such a microwave oven was developed around 1965 and about 150 units were produced at VEB Elektrowärme Sörnewitz. It was intended for use in the catering trade.

Although the units were used in fast food restaurants for a while, the cost/benefit ratio was very unfavorable. The device needed a three-phase mains connection, and even then there was a lack of a necessary environment such as prepared food (frozen food) or microwave dishes, so that the devices were not yet able to establish themselves at that time. It was not until the 1980s, with the advent of powerful semiconductors, especially for the power supply part, that it was possible to produce microwave ovens economically, even for private households.

In the GDR such devices from own production did not exist. However, the WF had developed a magnetron ready for this purpose. It was no longer used for GDR microwave ovens.

Photo archive and development reports from the years 1945 – 1989

The Industriesalon strives to research the “Industrial History of Schöneweide”. The collection rescued by the association also includes all development reports of the WF from 1945 to 1989. Furthermore, about 30,000 photos could be recovered by the Industriesalon. They document products, technical developments, research and political and social life at the WF. They also include numerous portraits of plant employees – most of them photographed for publication in the WF newspaper “Sender” or for company ID cards.

Many photos are in a deplorable condition. They need to be inventoried and carefully stored. Volunteers meet in the industrial salon to try to identify and describe the people, occasions, operating procedures, etc. depicted in the photos – a very important prerequisite for being able to work with this valuable stock in the future.

If you are also interested in looking through the photos – please contact the industrial salon!

Deutsch

Deutsch Polski

Polski